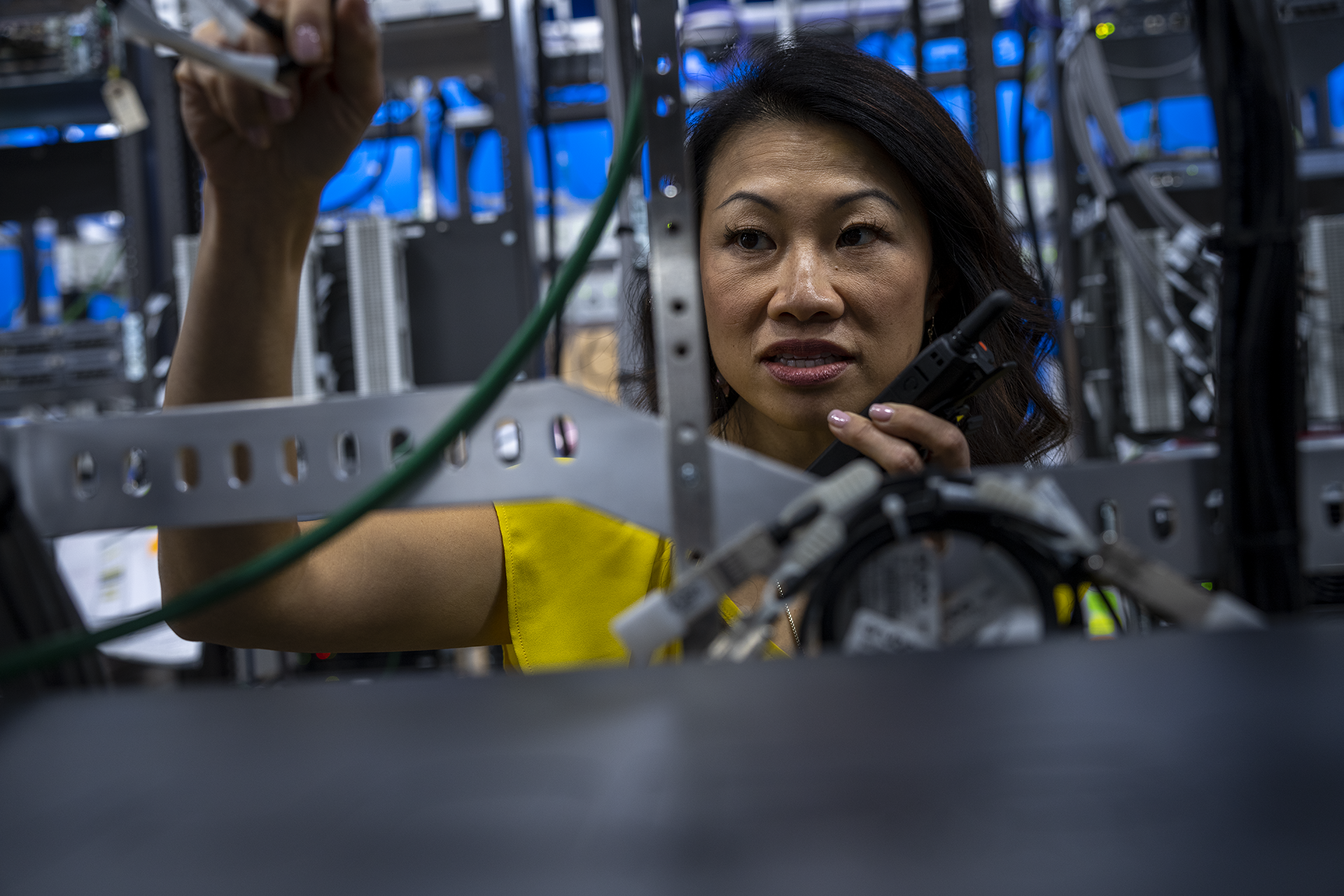

Anyone who’s ever worked in a factory or warehouse before knows they can be very large and loud places. When an issue arises on the manufacturing floor, it can be a challenge to coordinate efforts between the production, maintenance, and security teams to resolve it quickly and safely. This is where BAYCOM comes in! From camera systems to two-way radios, BAYCOM has all the industrial communication systems you could ever need.

We wanted to take the time to highlight some of our manufacturing and logistic projects this past year:

K&S Manufacturing – Ixonia, WI

Customer Problem

K&S Manufacturing is a company that designs and manufactures metal components. They needed to secure their main entrance as well as access to the shop areas to ensure their staff was safe and secure. The customer wanted to enhance the safety of their employees by ensuring only authorized individuals could access the worksite.

Problem-Solving Process

From our sales team visiting their site to learn more about their security needs to our engineering team implementing their solution, K&S Manufacturing was impressed by the diligence to make sure we were providing the customer with a solution specific to their unique needs.

Our team placed card readers throughout the facility as well as installed a video card reader for their main entrance for extra protection. We were also able to go above and beyond to K&S specific ask for a panic button! Our team implemented the panic button with the HR department for an extra sense of security when they need it the most.

BAYCOM Solution

We have completed K&S solutions in two phases so far, with a third phase for additional security in the works!

- Phase 1: Two Card readers installed & Video Reader Intercom

- Phase 2: Five additional card readers & Panic Button

At BAYCOM we know every manufacturing facility is different and needs solutions tailored to their specific needs. K&S continues to compliment our team on being able to listen to their needs, but also provide our unique perspective and expertise to make sure they are as secure as possible.

LaClare Family Creamery – Malone, WI

Customer Problem

LaClare is a goat cheese manufacturer that partners with local Wisconsin farmers who product high quality goat milk. They were having issues with reception in their factory and needed a reliable solution for constant communication without interruptions.

Problem-Solving Process

The BAYCOM team was able to visit their manufacturing facility and learn more about where LaClare was dealing with the worst of the reception issues. After listening to the customer and understanding the problem, we know the solution was a repeater system.

Our engineering team quickly went to work implementing a new repeater, antenna and identifying radios that needed reprogramming that would allow for full coverage across the facility with the proper reception for continuous communication.

BAYCOM Solution

LaClare is now fully functioning with:

- New Repeater

- New Antenna

- 40+ Radios Reprogramed onsite

- Several new radios to replace broken ones they had found while doing an inventory count

BAYCOM was able to accommodate LaClare last minute to get new radios in place so there was no lapse in communication when they found the broke ones during inventory. LaClare was impressed with our turnaround time and couldn’t be more thankful. The customer understands how important we take constant communication for the moments that matter.

Aldi Distribution Center – Oak Creek, WI

Customer Problem

Aldi needed dependable communication throughout the distribution center including hard to reach area in the freezer and cooler storage areas. They also needed numerous channels for various talk groups to maintain reliable communication.

The Aldi Distribution center is approximately 600,000 square feet with a 50,000 square foot cooler expansion currently being added to it. The distribution center consists of a large warehouse storage as well as several large freezer and cooler storage areas. It was important to Aldi to have reliable communication lines throughout the manufacturing floor ensuring safety within the entire worksite.

Problem-Solving Process

Aldi had been talking with a representative from another radio brand who told them they would need to install an antenna at the doorway at every cooler and freezer for communication. The complicated infrastructure with a lot of cable runs from their quote inclined their team to reach out to BAYCOM for a second opinion and to learn more about Motorola two-way radio solutions.

Our BAYCOM team went to look at the warehouse and learned more about the communication needs the customer wanted to improve upon. Our Communication Consultant, Doug, suggested setting up a temporary demo antenna and one repeater on the roof, along with 6 portable radios to test at their convenience. Adli was immediately thrilled as the other company would not set up a demonstration of their repeater and equipment. Our engineering team quickly went to work to design the infrastructure and identify the portable radios that would allow for full coverage across the 2-acre campus, with the sound quality and clarity that worked I their loud manufacturing environment.

Aldi had the demonstration system for several weeks and tested the radios throughout the complex and other areas on the property. Their team was more than impressed with the demonstration system, had perfect coverage throughout the property and from within the coolers and freezers to anywhere else in the complex!

BAYCOM Solution

Adli has moved forward with BAYCOM and so far, we’ve installed:

- Two Digital Repeaters and two roof mounted antennas. Initially started as one repeater but Aldi decided to have four repeated channels instead of two. Remaining channels are simplex.

- Approximately 80 Digital Radios consisting of 4 different models depending on what department they were going to be used in.

They could not be happier with the results and feel relieved to have a solution they can rely on throughout their entire distribution center. They feel safe and secure knowing the instant communication that can be made at any time for any situation, big or small.

RGL Logistics – Green Bay, WI

Customer Problem

RGL Logistics is a nationwide transportation and logistics company that needed access control and cameras to secure their multiple manufacturing warehouses in the Fox Valley Area.

The customer wanted to improve efficiency by granting access to contractors and visitors for the appropriate time of their onsite visits. It was important to enhance the safety of their employees by ensuring only authorized individuals could access the worksites.

Problem-Solving Process

BAYCOM has secured their Green Bay and Appleton warehouses, so it was an easy call for RGL to reach out to their BAYCOM representative to secure their newest location in Neenah.

Our team was able to visit their new location and our engineering team quickly went to work to design the infrastructure in the new location for access control and cameras to secure the warehouse.

BAYCOM Solution

In total, BAYCOM has helped RGL with over 18 different projects including adding:

- Cameras & Access Control

- Cabling

- Moving Equipment

- ~100 New Cameras

- ~50 Card Readers

RGL is a great example of a customer that is a BAYCOM advocate and felt confident in our team to secure their newest location. Our team works hard to build strong relationships and prove time after time we are here when they need us the most.

BAYCOM is proud to be able to assist in securing each warehouses needs with voice, video and data solutions that meet each companies’ specific needs. Our goal is to help these organizations operate safely and with maximum efficiency. While we only highlighted four of our many projects, we are thankful for each and every one trusting us to keep their facilities secure and safe!